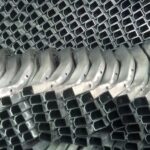

Tube Bending

Pierce Over Mandrel

We Create And Turn Your Design Into Reality

About Us

ERIN INDUSTRIES, INC. is a world class supplier for all your metal fabrication needs.

ERIN INDUSTRIES, INC. is a privately owned and operated metal tube fabrication company in southeastern Michigan’s growing community of Walled Lake. Housed in a 50,000 square feet manufacturing facility in downtown Walled Lake, ERIN INDUSTRIES, INC. has close ties to both the business community and the local community. With close proximity to highways and outside plating, painting and brazing facilities ERIN INDUSTRIES, INC. is in an ideal location for business.

We Can Do It

Our Products

Tie Bars

Upper and Lower Tie bars for front ends of vehicles. Radiator supports and front clip tubes.

Brush Guards

A grille guard or brush guard typically provides full-width coverage of the front end including the lights, grille and lower bumper area.

Cross-over Tubes

These crossover tubes connect the fluid flow from the front to the rear of the assembly. Brake, transmission, and regulator applications.

E.G.R Tubes

EGR tubes direct exhaust gases from the exhaust manifold through the EGR system and recirculate them into the combustion chambers.

Engine Coolant Lines

Radiator and coolant hoses carry coolant from a vehicle's radiator to its engine to cool the engine and prevent overheating .

Exhaust Components

Manifolds, over axle tubes, h-pipes, x-pipes, y-pipes or a full exhaust system.

Quality, Service, Reliability

Company Mission

IN-House capabilities include

Our Capabilities

Our team is proficient in an array of services that can help meet the final design vision.

Brazing and Soldering

Brazing and soldering, in essence, are the same in that they both melt the filler metal (braze or solder) only, not the base materials.

Assembly

If you are assembling a angled fitting, use an adapter of the correct size in the vice jaws and screw the angled hose end to this, make sure it is tight.

Drilling

This high-quality decoking hose provides many years of trouble-free service. Application: Mud, Mud Booster/Jumper, Decoking...

Endform and Swaging

The tube end forming process is usually used for a connection to other tubes, hose or other objects. There are different types of tube end forming.

Materials

We process a variety of Metals

- Low-carbon Steel

- Stainless Steel

- Chrome-moly

- Aluminum

- Copper

- Brass

- Alumanized Steel

- Galfan

- Titanium

- Steel Pipe